Hot-Dip Galvanized (HDG) bolted panel water tanks require a range of accessories to ensure functionality, safety, compliance, and longevity. Here’s a comprehensive list of common accessories, categorized by purpose:

1. Tank Structure & Assembly

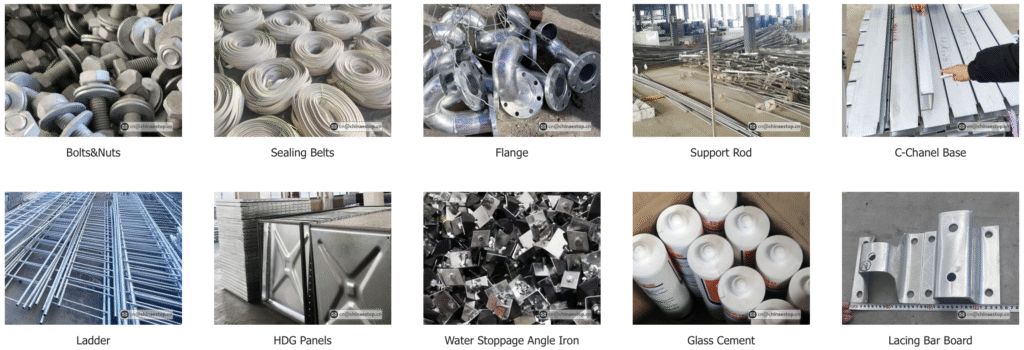

Bolts, Nuts & Washers: High-strength galvanized steel fasteners (ASTM A325 or equivalent) with sealing washers.

Sealing Gaskets: EPDM or neoprene gaskets for watertight joints between panels.

Corner Plates & Reinforcement Kits: For structural integrity at corners and connections.

Anchor Bolts & Base Channels: To secure the tank to the foundation.

2. Water Management & Flow Control

Inlet Pipes: With strainers to prevent debris entry.

Outlet Pipes: Often with vortex breakers (essential for pump suction to avoid air entrainment).

Overflow Pipes: Sized ≥1.5× inlet diameter, directed away from the foundation.

Drain Valves: For complete tank drainage (ball valves common).

Manholes: Roof and/or wall-mounted (DN500–DN600) with gasketed, bolted covers for internal access.

Baffle Walls (for large tanks): Reduce water sloshing and sediment resuspension.

3. Ventilation & Protection

Ventilators (Breathers):

Mesh-Ball Vents: Prevent insects/debris entry while allowing air exchange.

Louvered Vents: For high-dust environments.

Insect/Vertebrate Screens: Stainless steel mesh for overflow/vent openings.

Lockable Access Covers: Security against tampering or contamination.

4. Water Quality & Corrosion Protection

Internal Linings (for potable water): NSF 61-certified epoxy or polyurethane coatings.

Sacrificial Anodes: Zinc/aluminum rods mounted inside to protect against corrosion (critical for stagnant water).

Sediment Traps/Sumps: Low-point drains to capture sludge.

Water Level Indicators: Gauge glasses or electronic sensors.

5. Safety & Access

Internal/External Ladders:

Caged Ladders: OSHA-compliant external access (for tanks >20 ft/6 m tall).

Internal Ladders: For maintenance (corrosion-resistant design).

Safety Rails & Platforms: Roof guardrails and work platforms.

Anti-Vortex Plates: Prevent air suction at outlets.

6. Inspection & Maintenance

Sample Taps: For water quality testing.

Cleaning Hatches: Smaller access points for hose entry.

Overflow Alarm Systems: Notify of overfilling.

Cathodic Protection Test Points: Monitor anode effectiveness.

7. Optional/Specialized Accessories

Insulation Kits: For freeze protection or temperature control.

Mixing Systems: Aerators or agitators to prevent stagnation.

Roof Support Columns: For large-diameter tanks (>15m).

Seismic Bracing/Kits: For earthquake-prone zones.

Bird Deterrents: Spikes or nets to prevent nesting.

Key Considerations:

Material Compatibility: All accessories must be galvanized or stainless steel (AISI 304/316) to avoid galvanic corrosion.

Standards Compliance:

Potable Water: NSF/ANSI 61, WRAS, EN standards.

Fire Protection: NFPA 22 requirements (e.g., screened vents, seismic design).

Customization: Accessories should match tank dimensions/loads (e.g., roof manholes rated for worker weight).